When it comes to enhancing infrastructure and ensuring safety in various industries, covered FRP grating has emerged as a reliable and durable solution. The demand for high-quality products, especially in sectors like construction, petrochemicals, and marine, has driven the interest in pultruded FRP grating. In this all-inclusive guide, we’ll explore critical considerations for purchasing covered FRP grating and provide insights into buying pultruded FRP grating, ensuring you make informed decisions for your specific needs.

Understanding Covered FRP Grating

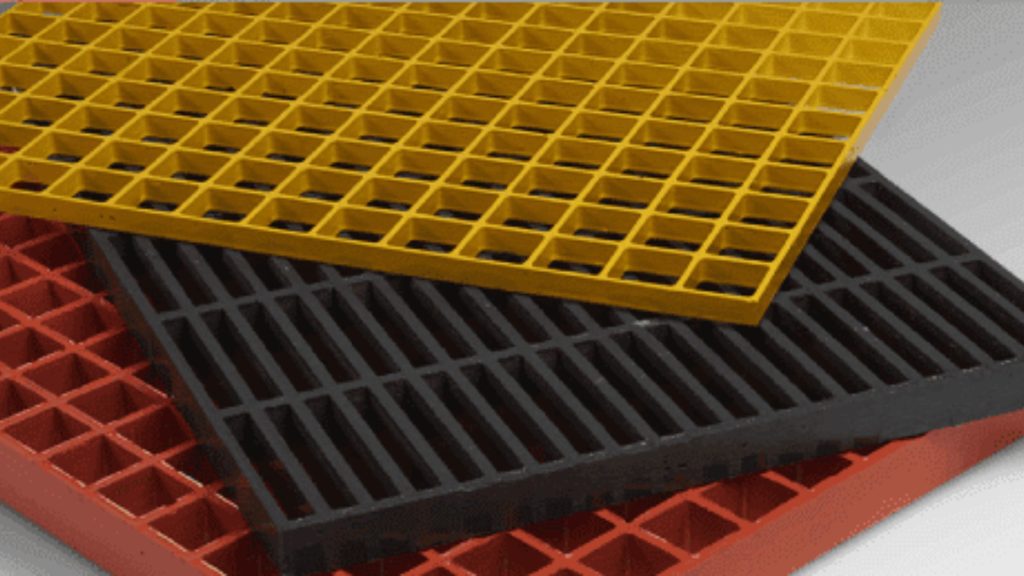

Covered FRP grating, or fiberglass-reinforced plastic grating, is a versatile and corrosion-resistant material widely used in industries where traditional materials might fall short. The term “covered” refers to the protective surface layer, adding an extra shield against environmental factors. This type of grating is known for its strength, durability, and capability to withstand harsh conditions.

Key Features of Covered FRP Grating:

Corrosion Resistance: Covered FRP grating is immune to corrosion, making it ideal for applications in corrosive environments such as chemical processing plants.

Lightweight: Compared to traditional materials like steel, covered FRP grating is significantly lighter, making installation and handling more manageable.

Slip Resistance: The surface of covered FRP grating is designed to provide excellent slip resistance, ensuring a safer working environment.

Low Maintenance: With its resistance to corrosion and aging, covered FRP grating requires minimal maintenance, reducing long-term costs.

Customization: Available in various sizes, colors, and specifications, covered FRP grating can be tailored to meet specific project requirements.

Now, let’s delve into the essential considerations when looking to buy covered FRP grating for your project.

Choosing the Right Type for Your Project

Before diving into the market, assess the specific needs of your project. Different industries may require variations in grating specifications, such as mesh size, panel thickness, or load-bearing capacity. Understanding your project requirements will guide you in selecting the most suitable covered FRP grating.

Installation Factors for Covered FRP Grating

Proper installation is crucial for the efficacy and durability of covered FRP grating. Consider factors such as support structure, anchoring methods, and environmental conditions. Ensuring that the grating is correctly installed will contribute to its optimal performance over time.

Maintenance Considerations

While covered FRP grating is known for its low maintenance requirements, understanding the recommended cleaning and inspection procedures is essential. Regular checks can help identify any issues early on, preventing potential hazards and ensuring the longevity of the grating.Now, let’s shift our focus to another critical aspect of the market: buying pultruded FRP grating.

All About Pultruded FRP Grating

Pultruded FRP grating is another variant that offers specific advantages, particularly in applications where high strength and stiffness are paramount. Pultrusion is a trading process that produces continuous lengths of reinforced profiles with a consistent cross-section.

Key Advantages of Pultruded FRP Grating:

High Strength: Pultruded FRP grating provides exceptional strength, making it suitable for heavy-duty applications, such as industrial flooring.

Stiffness: The pultrusion process imparts rigidity to the grating, ensuring stability and load-bearing capability in demanding environments.

Chemical Resistance: Pultruded FRP grating exhibits resistance to a extensive variety of chemicals, enhancing its suitability for various industries.

Fire Retardant: Many pultruded FRP grating products are intrinsically fire-resistant, providing an extra layer of safety in specific applications.

Selecting Pultruded FRP Grating

When considering the purchase of pultruded FRP grating, it’s essential to focus on specific factors that align with your project requirements.

Load Capacity and Span: Evaluate the load capacity and span requirements for your project to ensure that the chosen pultruded FRP grating can withstand the intended loads without compromising performance.

Resin Type: Different resin formulations offer varying degrees of chemical resistance. Select a resin type that aligns with the chemicals present in your operating environment.

Surface Characteristics: Assess the surface of the pultruded FRP grating to ensure it meets safety standards, especially regarding slip resistance.

UV Resistance: If the grating will be exposed to sunlight, opt for pultruded FRP grating with UV resistance to prevent degradation over time.

Conclusion:

In the realm of covered and pultruded FRP grating, Kentec Composites stands out as a reliable provider of high-quality solutions. While this guide has provided valuable insights into the considerations for purchasing FRP grating, the ultimate assurance of quality lies in choosing a reputable supplier.

Kentec Composites has established itself as a trusted name, delivering FRP grating solutions that meet industry standards and exceed customer expectations. As you navigate the market for FRP grating, consider the expertise and commitment to quality that Kentec Composites brings to the table. Your project’s success and the longevity of your chosen FRP grating depend on the decisions you make today. Choose wisely and ensure a durable and reliable solution for your infrastructure needs.